Background

A semester long project that I completed with the help of four group members. The project was based on an incident that occurred in 1987, where a mechanical failure of a mine gate at the Levack mine in Sudbury, Ontario resulted in the deaths of four employees.

The goal of this project is to create an improved mine gate design that will reduce the risk of failure and withstand over 20 tons (short ton) of static load. This project developed my abilities in problem scoping, decision making and idea generation, as well as tested my knowledge of engineering codes and regulations. We also considered the economic, societal and environmental impacts of our proposed final project.

Click here to view a pdf of the final report.

The Project

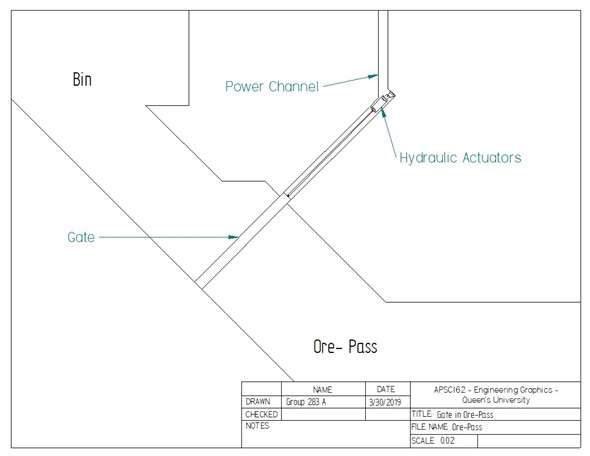

We came up with three possible design solutions included the Undercut-Arcing Gate, Pinching Gate and Drill Gate. The Undercut-Arcing design is an arced gate that will distribute the load like an arched bridge. The pinching gate design consists of two doors that exit from the ore-pass walls and pinch together with interlocking teeth. The final design is the drill gate, which consists of multiple inter-locking drill bits that can clear rock when closing. All designs were evaluated using an evaluation matrix based on client criteria.

Initially, the final design chosen was the Undercut Design, because of its feasible, simple, and effective force distribution. However, there are disadvantages of this design. For example, rocks could block the gate from closing by blocking its path of motion, since the Undercut requires more room than the other gate designs. As work progressed, the group discovered that the feasibility of the Undercut-Arcing gate was over-estimated. The biggest problem with the design was that its arc made it difficult for the gate to retract into the ore pass. To overcome this obstacle, the group came up with a new design.

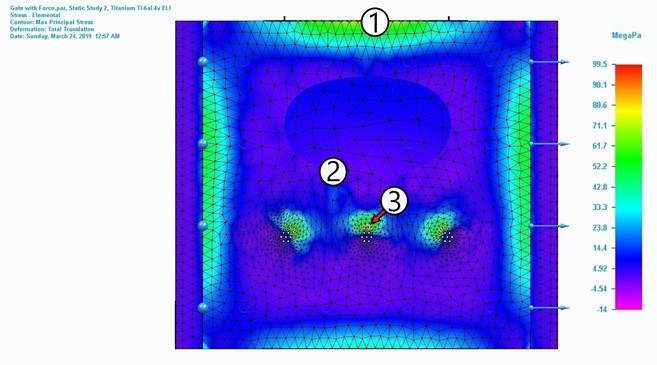

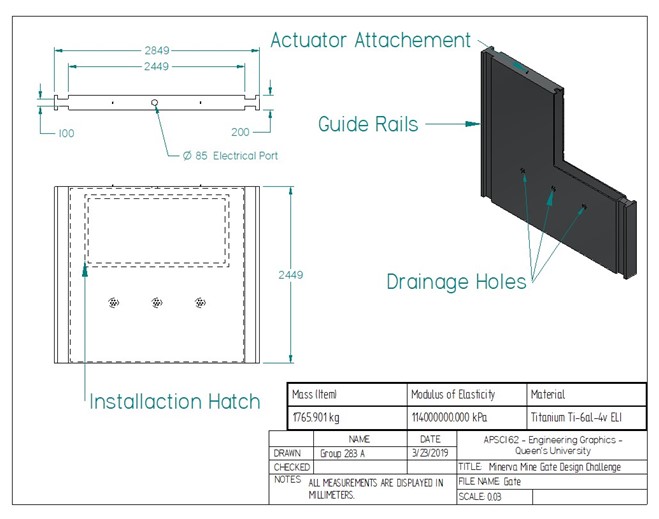

The new gate design is a hollow rectangle, which allows for bending moment resistivity, less material, and space for electronics. The gate was modelled using solid edge. A force analysis on the control gate was done to determine the stress distribution on the gate under 20 tons of loading. A financial analysis was made to determine the cost of the project and to justify the selection of certain materials. The total cost of the mine gate itself would be approximately $168,993.40 (CAD). In addition, the cost of the installation is estimated to be $100,000.00-$200,000.00 (CAD).